Ethanol Storage: A Comprehensive Guide to Safe Handling and Compliance

Ethanol, a versatile and widely used chemical, presents unique challenges in terms of storage due to its high flammability. Understanding and implementing proper ethanol storage procedures is crucial for safety, regulatory compliance, and environmental protection. This guide provides a comprehensive overview of best practices and essential considerations for safe ethanol storage.

Understanding the Risks of Ethanol Storage

Ethanol's low flashpoint (55°F/13°C) means it ignites easily, posing significant fire hazards. Furthermore, ethanol fires can be "invisible," burning with little visible flame, making detection and extinguishment difficult. This characteristic necessitates vigilant monitoring and the implementation of robust fire prevention and suppression systems. The consequences of a fire involving ethanol can be devastating, ranging from property damage and injury to significant environmental pollution.

Proper ethanol storage goes beyond simply keeping the liquid contained. It requires a multifaceted approach that addresses flammability, environmental concerns, and regulatory compliance. Ignoring these considerations can lead to severe consequences and hefty fines.

Flammability and Fire Prevention

The primary concern with ethanol storage is its extreme flammability. Because of this, the storage facility's design and construction are critical. Materials must be fire-resistant, and adequate ventilation systems are needed to prevent the accumulation of flammable vapors. The location of the storage facility relative to other buildings is also a key factor, influencing fire rating requirements. For example, closer proximity necessitates higher fire ratings for the building's walls. Regular maintenance and inspections of storage tanks, including leak detection, are vital for preventing accidents.

Regulatory Compliance and Standards

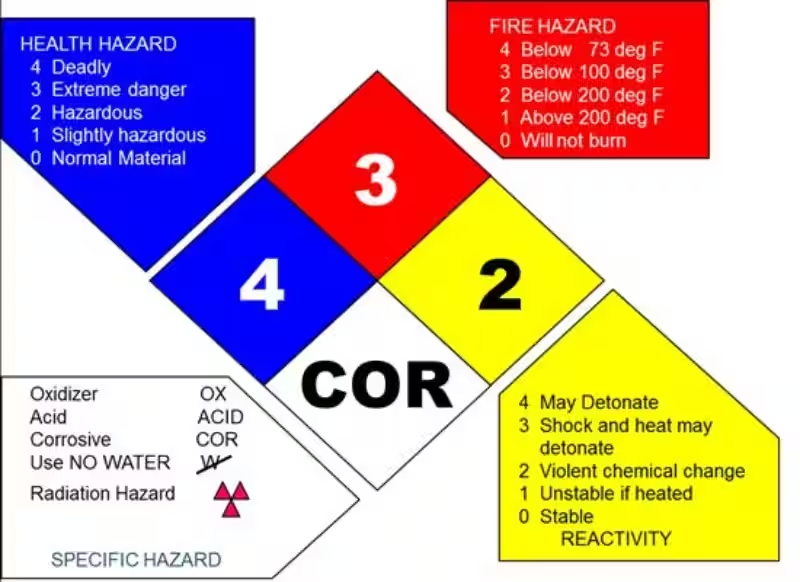

Safe ethanol storage requires strict adherence to various regulations and standards. Key among these are:

- OSHA 1910.106 (Flammable Liquids): This OSHA standard outlines requirements for the handling, storage, and use of flammable liquids, including ethanol.

- NFPA 30 (Flammable and Combustible Liquids Code): This NFPA code provides detailed guidance on the design, installation, and operation of facilities that store flammable and combustible liquids.

These regulations cover many aspects of ethanol storage, including building codes, tank design, ventilation, and emergency response plans. Failure to comply can result in significant penalties.

Building Codes and Storage Tank Specifications

Building codes dictate the use of fire-resistant materials in the construction of ethanol storage facilities. Storage tanks themselves must meet stringent requirements, including:

- Corrosion protection: To prevent leaks and spills.

- Secondary containment: Sumps or other systems to capture spills.

- Regular leak testing: To ensure the integrity of the storage system.

The distance between the storage facility and occupied structures significantly impacts the required fire resistance rating of the building. Closer proximity mandates higher fire ratings (e.g., 4-hour rating for less than 10 feet, 2-hour rating for 10-30 feet).

Labeling, Documentation, and Environmental Responsibility

Accurate and clear labeling is paramount for safe ethanol storage. Containers must be clearly marked with:

- Contents: "Ethanol" or "Ethyl Alcohol"

- Hazard warnings: Flammability and health risks

- Safety precautions: Handling instructions

- Emergency contact information: For immediate response in case of an incident.

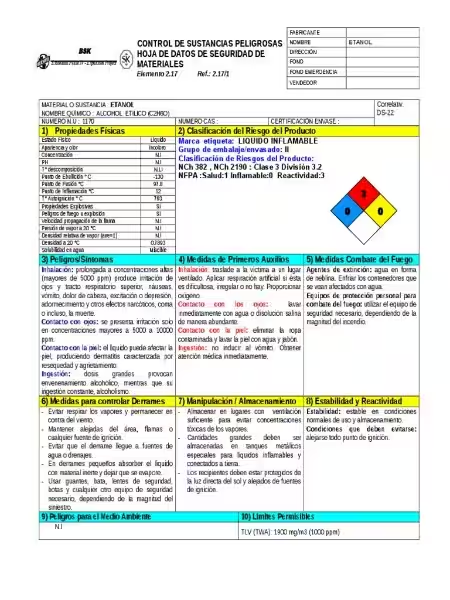

Maintaining comprehensive documentation is also essential for regulatory compliance. This documentation should include:

- Inventory records: Tracking ethanol quantities.

- Safety inspection reports: Documenting regular checks.

- Material Safety Data Sheets (MSDS): Providing detailed information on handling and hazards.

Environmental compliance is crucial. Regulations governing air emissions, wastewater management, and hazardous waste disposal must be strictly followed.

Temperature Control and Fire Safety Systems

Ethanol's flammability necessitates strict temperature control to minimize vapor production. Effective fire safety measures are essential and include:

- Fire suppression systems: Sprinklers, foam systems, or other appropriate methods.

- Emergency shutdown procedures: To quickly isolate the source of any potential leak or fire.

- Employee training: Comprehensive training for employees on fire prevention, detection, and response procedures.

The use of intrinsically safe electrical equipment minimizes the risk of ignition sources. For ethanol fires, allowing the fire to burn out under controlled conditions is often the safest approach, reducing the risk of uncontrolled spread.

Best Practices for Safe Ethanol Storage

Beyond regulatory compliance, several best practices contribute to safe ethanol storage:

- Dry storage: Ethanol should be stored in a dry area with low humidity to prevent water absorption. Water absorption can affect purity and increase flammability.

- Climate control: Climate-controlled storage buildings help maintain optimal temperature and humidity levels.

- Ventilation: Exhaust fans should be used to remove flammable vapors.

- Specialized facilities: Utilizing specialized storage facilities designed for flammable liquids offers enhanced safety features like built-in secondary containment and climate control. These facilities often provide professional management, reducing the burden on the user.

Proper ethanol storage is a multifaceted process demanding rigorous attention to detail and proactive safety measures. By adhering to regulations, best practices, and maintaining a culture of safety, risks associated with ethanol storage can be effectively mitigated.